Purified water preparation system

Category: Health equipment

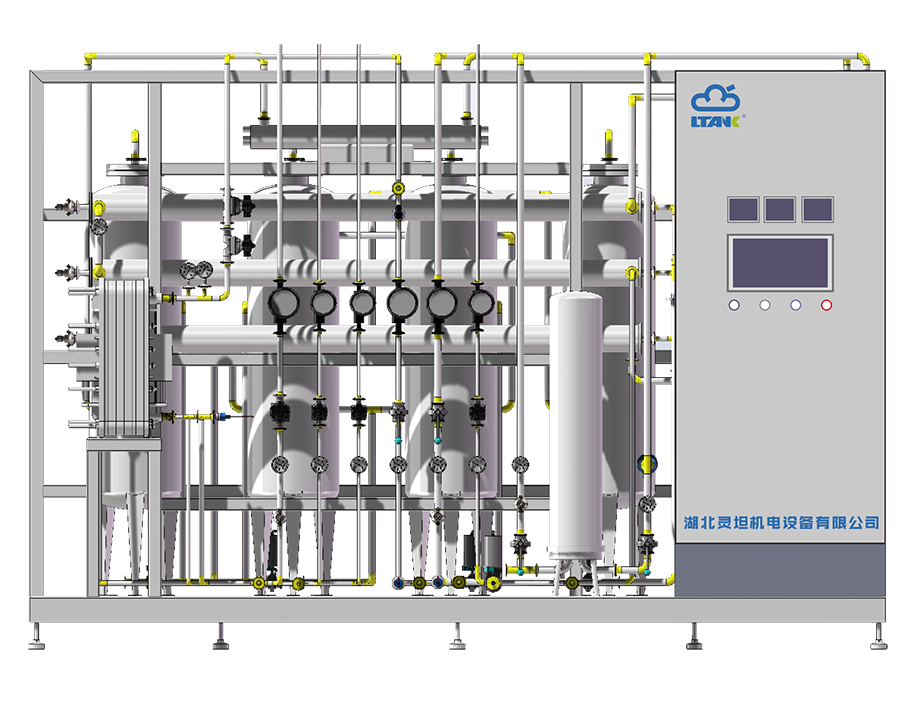

Introduction to Purified Water Equipment System

Purified water equipment, as a highly specialized water treatment equipment, is increasingly widely used in industries such as medicine, biochemistry, chemical engineering, and hospitals. This article will provide a detailed introduction to the system composition, working principle, classification, and application fields of purified water equipment, in order to help everyone better understand and apply this equipment.

System composition

The purified water equipment mainly consists of four systems: preparation system, control system, disinfection system, and distribution system.

The preparation system is the core of purified water equipment, mainly composed of pretreatment and reverse osmosis desalination. The pretreatment section includes sand filters and activated carbon filters, which are used to remove large particulate impurities, suspended solids, and residual chlorine from the water, reducing pressure for the subsequent desalination process. The reverse osmosis desalination section adopts a two-stage reverse osmosis device, which removes impurities such as dissolved salts, colloids, and suspended solids in the water through the filtration effect of the reverse osmosis membrane, ensuring the quality of the effluent.

The control system is the "brain" of the equipment, which monitors important indicators such as pressure, conductivity, and water temperature through a combination of centralized control and on-site control to ensure stable and efficient operation of the equipment.

The disinfection system is responsible for killing bacteria, viruses, and other microorganisms in water, ensuring the biological safety of the effluent. UV sterilization and plate heat exchangers are commonly used for pasteurization, effectively removing microbial contamination from water.

The distribution system consists of a closed-loop circulation pipeline and a purified water storage tank system, using a forced circulation water supply method to ensure that the water points can obtain high-quality purified water stably and continuously.

The working principle of the purified water preparation system mainly includes the following steps:

Pre treatment: Pre treatment is the first step in the preparation of pure water, mainly removing large particle impurities, suspended solids, colloidal substances, and organic matter from the water through methods such as filtration, precipitation, and adsorption. The purpose of preprocessing is to protect the subsequent processing equipment, extend its service life, and improve processing efficiency.

Reverse osmosis: Reverse osmosis is the core technology for pure water preparation, which utilizes the selective permeability of semi permeable membranes to press water molecules from high concentration solutions into low concentration solutions under high pressure, thereby removing harmful substances such as heavy metals, organic matter, bacteria, viruses, etc. from water and obtaining relatively pure water.

Post treatment: Post treatment mainly involves further purification and treatment of water after reverse osmosis, such as UV disinfection, ozone disinfection, etc., to ensure the purity and safety of the water.

The application fields of purified water preparation systems are very wide, mainly including:

Pharmaceutical industry: Purified water is an indispensable raw material in the pharmaceutical process, and its quality directly affects the safety and effectiveness of drugs. The pharmaceutical industry has extremely high requirements for the purity of purified water, usually requiring it to meet the standards of injection water or purified water.

Biochemical and chemical engineering: Purified water is widely used in experiments, research and development, and production processes as a solvent, reaction medium, or cleaning solution, which has a significant impact on the quality and performance of products.

Hospitals: Hospitals use purified water for cleaning, disinfecting medical equipment, and flushing during surgical procedures to ensure the safety and hygiene of the medical process.

Laboratory: The laboratory has very high requirements for water quality, and the purified water preparation equipment can provide high-quality experimental water to ensure the accuracy and reliability of experimental results.

Food industry: The food industry also has very high requirements for water quality. Purified water preparation equipment can provide production water that meets standards, ensuring the quality and taste of products.

Electronics industry: The electronics industry requires a large amount of high-purity water, such as semiconductor manufacturing, integrated circuit production, etc. Purified water preparation equipment can provide high-purity, low resistivity water to meet the needs of the electronics industry.